美国上市公司斯丹迪斯集团(Standex International Corp.)的下属企业斯丹迪斯雕刻集团(Standex Engraving)始建于1955年,总部位于美国。模德是斯丹迪斯旗下的子品牌。迄今为止模德已在美国、新加坡、澳大利亚、巴西、加拿大、中国、英国、日本、德国、意大利、墨西哥、挪威、西班牙、葡萄牙、捷克等22个国家设有46家生产企业。

2003年,模德进入中国,首家工厂在广东省东莞市成立。自此,模德在中国发展迅速,至今国内已有8家生产基地:模德东莞,模德苏州,模德天津,模德厦门,模德重庆,模德武汉,常州电铸工厂和斯丹迪斯泰纳贝。

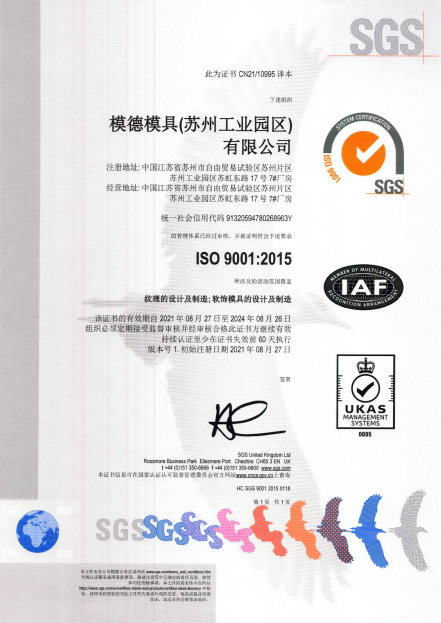

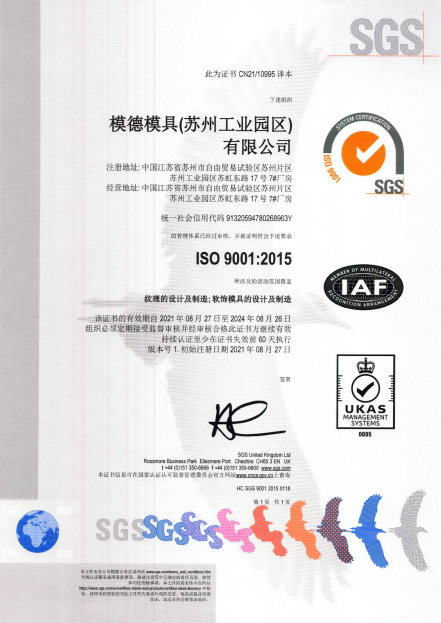

模德中国不断引进欧美最先进设备和工艺。2009年,模德中国引进首台专业纹纸打印机,对于纹理品质有了初步的数字化控制。大宽幅的打印(1100*1800mm)避免了大型模具产生拼接轨迹。2013年,模德中国引进五轴联动激光雕刻设备,弥补了传统化学蚀刻的不足。2014年,亚太区设计中心在苏州成立,开启了纹理设计理念上的全新变革,客户不再仅限现有纹理的选择,设计师可以融合产品定位,风格偏好,为客户量身定制体现个性化,品牌价值的专属纹理。2015年,模德中国引入镍壳搪塑技术,满足汽车行业主机厂对内饰件生产工艺更新迭代的要求。2016年,模德中国引入全新RTP高清3D打印设备,可在数小时内将纹理从图纸转换为实物效果。这不仅意味着纹理设计的周期大幅缩短,而且更能带给双方设计师更多的灵感和更加紧密的交互式沟通。2021年,模德苏州顺利通过 ISO 9001:2015 质量管理体系认证。

模德中国与众多汽车行业和非汽车行业客户建立了长期的战略合作伙伴,并具备稳定一流的品质及良好的售后服务。缔结合作的客户有:大众、宝马,长城,长安,东风,上汽,菲亚特、本田、丰田、九阳、苏泊尔、Apple, Dell, Zebra, 小米、海尔等众多国际知名企业。

模德模具(苏州工业园区)有限公司创立于 2005 年 7 月,经过近20年的发展,逐渐 从传统的纹理加工企业成长为一家集纹理设计、验证、开发、应用为核心业务的服务型公司。 2015年起公司引进了搪塑模具制造,阴模吸塑模具制造等先进工艺,研发团队以此为契机, 不断增强研发能力,提升人才建设和团队管理能力,先后获得了“苏州市蚀纹工程技术研究 中心(2013年)”,“国家高新技术企业(2016年 )” 、 “江苏省纹理研发设计与应用 工程技术研究中心(2019年)”、“苏州市企业技术中心(2020年)”、“苏州市瞪羚企 业(2020年)”、 “江苏省省级企业技术中心(2021年)”、 “苏州市企业工业设计中心 (2021年)”等荣誉,成为江苏省乃至全国第一家以纹理设计、制造及应用为基础的科研、 创新平台。

未来,研发团队将焦距增材制造、纳米功能纹理、激光加工等先进制造技术,建立一个 功能更加全面的纹理服务基地,坚持创新引领技术,持续强化自主研发能力,不断提升自身 核心竞争力,努力成为世界一流的企业。

焦距增材制造

焦距增材制造 纳米功能纹理

纳米功能纹理 激光加工

激光加工 更多先进制造技术

更多先进制造技术致匠心,所谓“执着”就是对事情"不放弃”,所谓“不放弃”也是一种“思想的深度”,从而淬炼心性,养成自己,唤醒每个人的一流精神。

感恩生活,生活将赐予你灿烂的阳光。

坚持自己的信念,完成理想的欲望和永不放弃的

坚持,是每个人拥有的最伟大的财富。

涓滴之水终可以磨损大石,不是由于它力量强大,

而是由于昼夜不舍的滴坠。

Copyright(C)2009 Mold-Tech China All right reserved. | 版权声明粤ICP备06121151号-1技术支持:

粤公网安备 44190002001606号